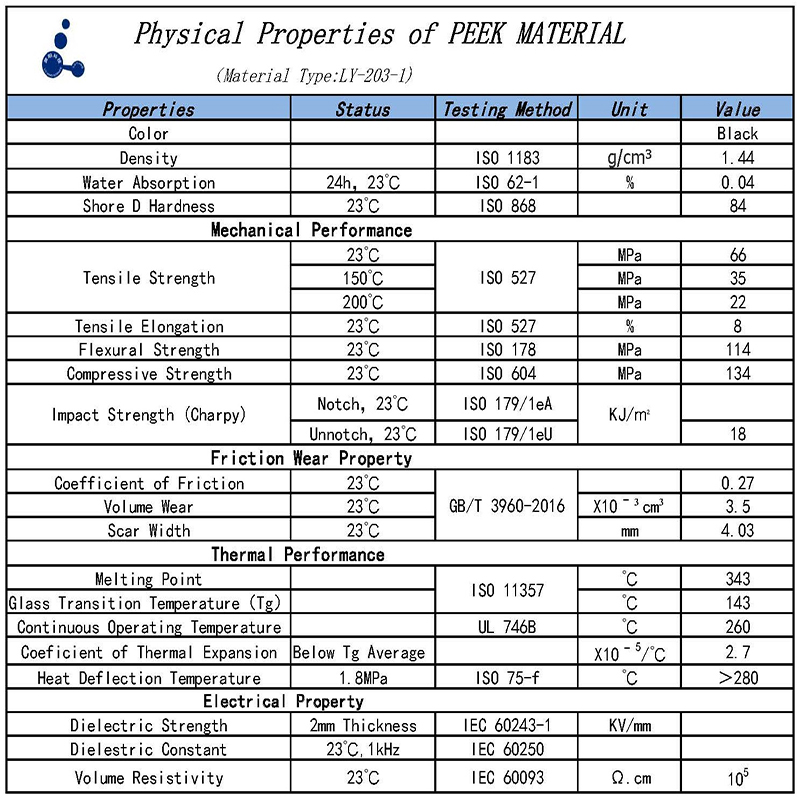

High - Temperature Resistance: The PEEK material equips the PEEK comb labyrinth seal (PEEK comb Seal)to endure searing temperatures. With a continuous operational temperature cap of 260°C and the capacity to tolerate even higher temperatures in short - term scenarios, the PEEK labyrinth seal(PEEK comb Seal) is eminently suitable for heat - intensive environments. In the petroleum sector, during operations like crude oil distillation, where equipment functions at elevated temperatures, the Polyetherketone Seal can uphold its structural soundness and sealing efficacy. The PEEK comb Seal (PEEK comb labyrinth seal)ensures the secure and efficient operation of the machinery.

Chemical Corrosion Resistance: PEEK demonstrates exceptional resilience against a wide spectrum of chemicals. Be it potent acids, alkalis, or diverse organic solvents, the PEEK comb labyrinth seal (PEEK comb Seal)can fend off corrosion. In the chemical industry, where pipelines and equipment frequently handle highly corrosive substances such as sulfuric acid or sodium hydroxide, this Polyetherketone Seal effectively defends against chemical assault. The corrosion - resistant trait of the PEEK labyrinth seal not only elongates its service life but also shields the equipment and the surrounding milieu from potential harm due to leakage.

Wear Resistance: In applications featuring high - speed rotating shafts, substantial mechanical stress and abrasion prevail. The wear - resistant essence of the PEEK comb Seal(PEEK labyrinth seal) enables it to endure these abrasive forces over an extended span. For example, in high - speed pumps employed in the pharmaceutical industry, where the shaft's incessant rotation can induce wear on the seal, the PEEK comb labyrinth seal(PEEK comb Seal) can withstand this wear. By maintaining its sealing function, it curtails the necessity for frequent maintenance and replacement, thereby enhancing the overall reliability and cost - effectiveness of the system. The PEEK labyrinth seal(PEEK comb Seal), with its wear - resistant Polyetherketone composition, plays a pivotal role here.

High Mechanical Strength: PEEK offers commendable mechanical strength and stiffness. This empowers the PEEK comb labyrinth seal to retain its shape and sealing performance under high - pressure conditions. In high - pressure hydraulic systems, the Polyetherketone Seal can bear the internal pressure, guaranteeing a tight seal. Moreover, PEEK's favorable fatigue resistance implies that the PEEK labyrinth seal (PEEK comb Seal)can endure repeated stress cycles without substantial degradation. This renders it apt for applications where the equipment is frequently activated and deactivated, such as in certain chemical processing units.

Advantages of PEEK shaft end comb seal:

1. PEEK labyrinth seal is simple, and installation does not require special tools or skills, making it convenient and fast.

2. Due to its excellent high-temperature resistance, chemical corrosion resistance, wear resistance, and high mechanical strength, PEEK labyrinth seal has a long service life and can greatly reduce maintenance costs.

3. PEEK labyrinth seal is suitable for various application scenarios of rotating shaft seals, such as pumps, compressors, mixers, and other equipment.

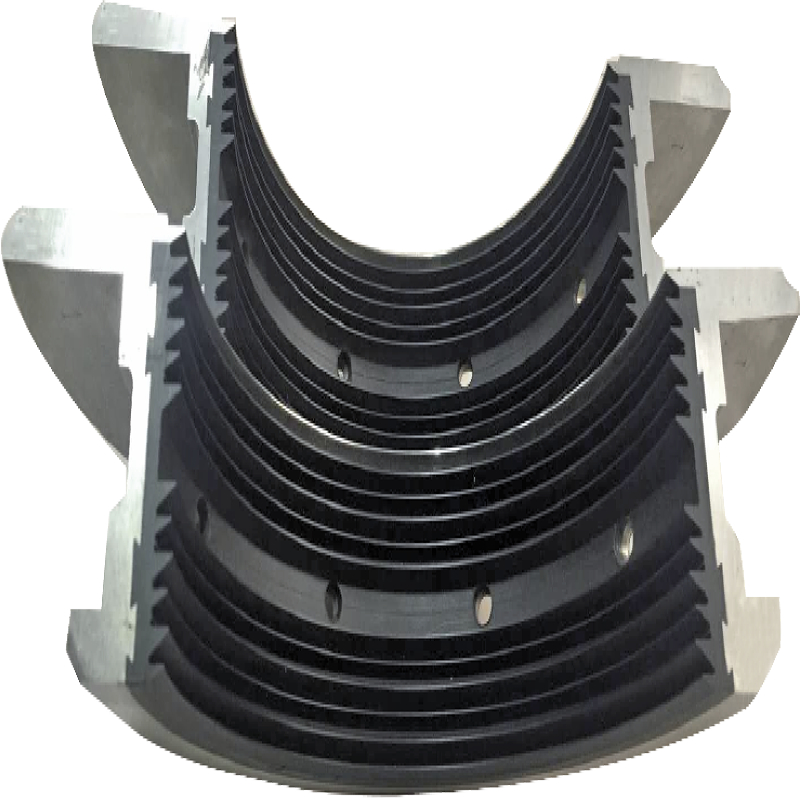

Details of PEEK shaft end comb seal:

Application of PEEK shaft end comb seal:

1. Polyetherketone Seal is suitable for high-temperature, high-pressure, and high-speed rotary shaft sealing applications, such as pump sealing and compressor sealing.

2. In the petroleum industry, Polyetherketone Seal can be used for sealing oil well pumps;

3. In the chemical industry, Polyetherketone Seal can be used for sealing various corrosive media such as acids, bases, and salts; In the pharmaceutical industry, Polyetherketone Seal can be used for sealing high-temperature sterilization equipment, reaction vessels, and other equipment;

4. In the food processing industry, PEEK comb Seal can be used for sealing various high-temperature sterilization equipment, mixers, and other equipment.

Why did you choose us?

Our PEEK material can maintain stable performance at high temperatures, effectively preventing deformation and aging of seals at high temperatures, improving sealing performance and service life.

We provide comprehensive after-sales service, including technical support, maintenance, etc., to ensure the normal operation of your equipment.